Additional equipment

OPTISAVE ELMED 6 + 6

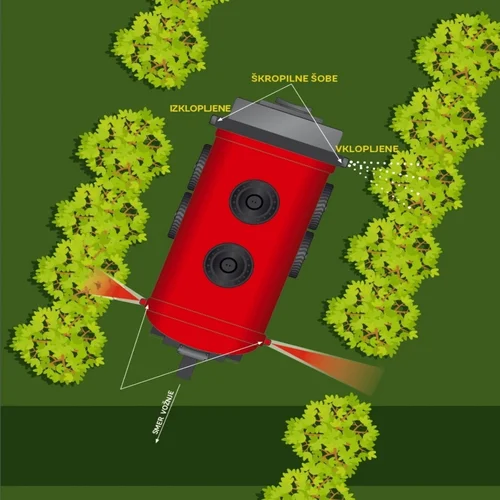

The new controller was developed by Elmed GmbH to optimize crop protection and increase the efficiency of detecting the leaf mass by means of the sensors (6 on each side) and, if necessary, spray sections (6 + 6) with spray nozzles opens or closes.

The technique: The new controller consists of:

- a compact control module with large illuminated 8 "LCD display and touch-screen operation.

- joystick with freely adjustable buttons

- a pressure sensor that measures the working pressure.

- the fast-switching Solenoid valves (6 + 6), for opening and closing the nozzles (50bar).

- an electric pressure regulator (50bar).

- a fill level sensor which measures the drum contents with the highest precision.

- a speed sensor for measuring the effective travel speed at the spray device.

Optional:

- a flow sensor that continuously measures the exact discharge quantity of the nozzles.

- a software for PC

The function in manual mode: In this function, the on-board computer becomes a normal electrical control for opening and closing the nozzles, as well as for electrical pressure adjustment.

The function in semi-automatic mode: The programmed working pressure is always kept constant by the on-board computer, even in changing situations by means of the control of the electrical pressure regulator. (e.g., opening / closing the nozzles).

The function in fully automatic mode: On the basis of the selected data and the effective, automatically read driving speed, the on-board computer calculates the correct ejection quantity, which it automatically adjusts by means of a pressure regulator. The ejection quantity continuously adapts to the changing driving speed, so that the selected application rate (lt / ha) is exactly maintained.

Programming on the PC:

- one-time input of all the properties for processing with all relevant injection-related data.

- one-time entry of all required, supplied pesticides with max. permissible quantity per hectolitre, or per hectare, their waiting periods and other informationen.

Creation of spray programs:

- selection of the property and the active ingredients to be used

- enter the desired concentration or discharge rate lt / ha and driving speed

- now the program automatically suggests the ideal nozzle size and calculates the necessary working pressure. This data can thus be transferred by mouse click on the control unit of the sprayer.

- in addition, spraying programs can be created on the sprayer itself or on the control module independently of the PC.

Display Features: The following data is displayed on the large LCD display:

- working pressure

- drum content

- driving speed (km / h)

- output quantity (l / min)

- total ejected amount

- application rate (l / ha)

- total processed area (ha)

- information on the property and active substance

- number of open sections

Advantages:

- simple and clear operation.

- constant display of all important spray data.

- recording of all actual data. no annoying calculation of the working pressure.

- if the ideal pressure and the travel speed exceed or fall below an acoustic signal.

- also acoustic signal with nozzle clogging.

- large main memory for 10,000 spray programs and many more.

- only one-time programming, reuse.

- always accurate application rate, no residual quantities (cost-saving and environmentally friendly).

- when filling the sprayer, the required data such as filling quantity, active ingredient and dosage can be queried.

Benefits:

- working speed up to 11 km / h

- identification of the object up to 3.5 m from the sensor and 8 mm diameter.

- significant savings when using PPPs